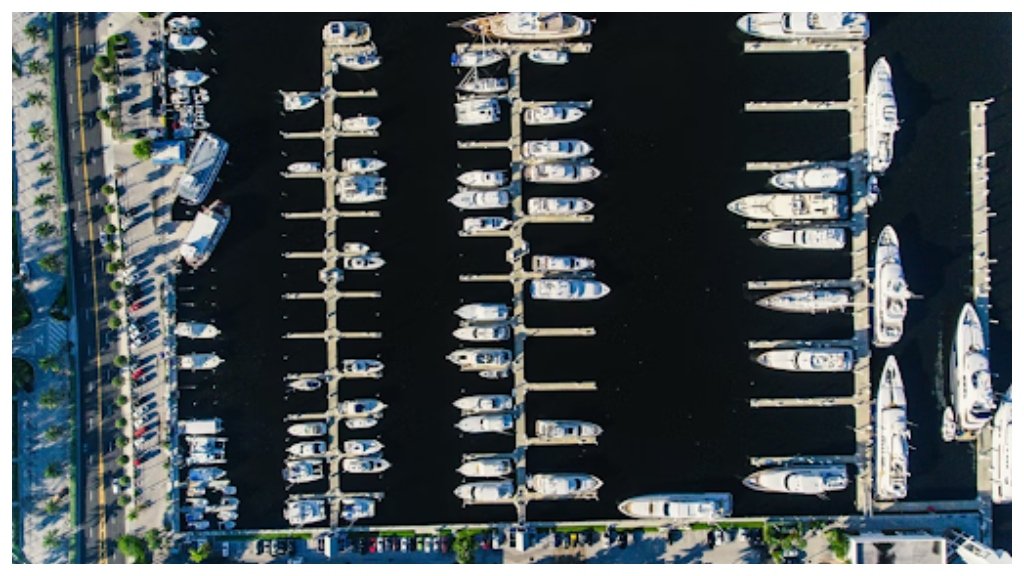

In today’s marine sector, efficiency, safety, and sustainability have never been more important for marina developers and operators along the waterfront. As the marine industry evolves, so does the methodology for docking watercraft. The industry has largely moved away from traditional, tedious, labor-intensive docking methods which led to system wear and tear . As the marina industry embraces smarter and autodock systems, drive-on boat dock solutions are revolutionizing businesses’ watercraft operational methods.

B2B companies in marina management, boat manufacturing, aquaculture and construction along the waterfront can now more seamlessly and efficiently integrate custom boat docks into their waterfront infrastructures. Designed to optimize workflows and enhance safety while lowering maintenance costs, dock systems are fast becoming a staple in the design of today’s marinas.

This article looks into the impact of drive-on dock systems on the efficiency of marinas and the customization of dock systems to enhance waterfront management.

The Evolution of Modern Docking Systems

For decades, marinas have relied on slip or mooring systems. These systems, while effective, are often time-consuming to maintain and require manual docking along with the use of ropes and complex underwater anchoring. The driven boat dock systems have more efficiently and innovatively solved industry docking operational inefficiencies.

Today’s technologies enable boats and personal watercraft (PWCs) to drive on and off the dock, which removes the necessity of lifts and hoists. Consequently, docking takes much less time because exposure to water is damaging and time-consuming. Daily operations become much more efficient.

Technology improvements drive a more efficient, safe and sustainable operational model for the marina

Key Advantages of Drive On Boat Dock Systems for Marinas

Professional marinas are experiencing the benefits of drive-on systems and are jambing them into their designs because of the vast operational, financial and ecological benefits.

- Increased Efficiency

Time for docking and launching is dominated by alignment, rope tying, and manual stabilization. Drive on docks remove the need for these time-consuming steps as boats can sail into the parking space and docking is done. This streamlines the process and enables more marina traffic.

- Lower Costs for Maintenance

Storage gives boats adequate protection and avoids direct exposure to the elements. As a result, there will be a lower rate of corrosion andSettlement of, and barnacle growth, a result, and algae. This will also reduce the hours and rates spent cleaning and maintaining the vessel.

- Greater Protection

The stable floated design of the dock and its non-skip surface minimizes the chance of accidents when boarding and disembarking. It also lessens the potential for scratches and impact scratches on the hulk, a problem common with stationary docks.

- Longevity and Durability

Drive-on systems of marine grade aluminum and high-density polyethylene (HDPE) being of quality and high-value, are

impact-resistant and corrosion-resistant. They also can resist UV rays and are

weather flexible. They will perform well and resist to extremities.

- Environmentally Friendly Design

Floating systems are environmentally responsible choices for marina projects. The marine systems of modular and the environment systems that will be used can be recycled at the end of their life.

These systems leave B2B customers with durable operating costs and a better

environmental profile and quality of service.

The Importance of Customization when Creating Efficient Marinas

Marinas are not identical. With the depth of water, the movement and the type of boats used, and with the volume of traffic (which will, of course, affect the layout of the entire) systems. That’s why custom boat docks are critical for achieving efficiency.

Site Specific Design in Custom docks are built especially for the topography and hydrodynamic conditions of specific locations. Engineers consider wind exposure, the current of the water, and the type of boats for optimal stability and usability. Modular Flexibility Modular floating systems can be expanded and reconfigured at little cost. If a marina expands or changes its layout, sections can be added or removed without expensive reconfiguration. Integration of Utility Systems in Modern docks can incorporate power, lights, and water supply systems into the floating platform. This increases the service experience and provides conveniences to boat owners. Adaptability to Multiple Vessel Types Custom docks can be designed to fit a range of hull shapes and sizes, from jet skis and fishing boats, to large commercial vessels. This adaptability makes sure the infrastructure is useful for a wide range of business needs. Aesthetic and Branding Opportunities in Custom docks also allow for high-end design which is often required for marinas and resorts. Custom surface finishes, color schemes, and branding can be designed for visual coherence and to increase corporate identity. Customization gives marinas the ability to balance functionality, efficiency and design innovation.

Sustainable and Smart Engineering in Modern Marina Development

Today, marina operators need to balance commercial and development environmental stewardship. With floating docks, the principles of sustainable design and smart engineering are married to meet these objectives.

Eco-Conscious Materials

Using recyclable materials, such as HDPE or aluminum, results in a minimal environmental footprint. Furthermore, these materials do not slip into a decaying state or leak chemicals that compromise water quality.

Minimal Seabed Impact

Without the need for extensive dredging or deep pilings, floating docks safeguard marine life and preserve the natural flow of water.

Long Lifecycle and Low Waste

Construction of floating docks is a one-time event for decades, and durable building materials are the main factor to reduce long-term costs and waste.

Smart Dock Innovations

Modern custom boat docks incorporate smart features, such as monitoring sensors, automated lighting, and power management systems. Marina managers can use these technologies to streamline operational control and gain visibility in energy management.

Weather-Resilient Engineering

Drive-on docks remain as reliable, adaptable, and stable assets in areas that experience extreme weather and seasonal changes.

By using these eco-innovative materials, systems improve the operational performance of the marina, while also providing essential sustainability, a growing priority for relationships with B2B partners and global investors.

Choosing the Right Partner for Drive-On Dock Projects

Dependable suppliers with a firm grasp on the fundamentals of marine engineering are critical for the completion of any marina project. Working with a qualified floating dock manufacturer has the experience to know what technical and ecological constraints are placed on the designs and what solutions are needed.

Industry Expertise and Experience

Make sure to select companies that have built a strong reputation with large commercial projects. Expert partners recognize and mitigate risks while creating effective solutions.

Engineering and Design Capability

A qualified professional team should evaluate the site, perform buoyancy and environmental assessments, and provide a working design for the dock.

Customization and Scalability

You should choose a manufacturer that has adaptable systems designed to meet the demands of future expansions. Modular systems can be easily fitted to accommodate greater levels of traffic.

Compliance and Certification

All products should meet internationally recognized compliance and quality standards, such as ISO or CE. This will provide peace of mind for the longevity and reliability of the product.

After-Sales and Technical Support

A dependable partner offers technical support, spare parts, and maintenance advice. This will ensure that the partner can provide the best experience over the full life cycle of the product.

Making the correct partner choice from the start leads to a marina that has the most eco-friendly and high-tech infrastructure.

Conclusion

Operational efficiency and sustainability are key for long-term success in the marina management industry. Drive-on boat dock systems are a more intelligent and practical option for modern marine operations. These systems are flexible, durable, and cost-efficient.

Custom boat docks improve space utilization, increase workflow efficiency, reduce maintenance costs, and sustainably develop marine infrastructure. Click here for more information.

Custom boat docks improve space utilization, increase workflow efficiency, and reduce maintenance costs. Designed and engineered custom boat docks support environmentally sustainable marine infrastructure development.

For large marina, aquaculture, and port commerce, the drive-on systems offer adaptable solutions meeting advanced B2B operational demands. The systems are the essence of the future marine efficiencies; a safer, smarter, and sustainable future.

With the continued development of materials and technologies, the collaboration of innovation with environmental care will keep floating docks engineered to enhance the marine environment, and to touch business the success of floating docks providing global infrastructure to marinas. The success for the business will be for decades.