Protecting electronic components is crucial for ensuring their longevity and reliable performance.Cost-Effective Ways to Protect Your Electronic Components Environmental factors like moisture, dust, temperature fluctuations, and physical impact can cause significant damage, leading to costly failures and repairs. While high-end protection methods can be expensive, several cost-effective solutions offer robust defense without straining your budget. This listicle explores practical and affordable ways to safeguard your valuable electronics, helping you extend their lifespan and maintain optimal functionality.

1. Conformal Coatings

Conformal coating is one of the most popular and economical methods for protecting printed circuit boards (PCBs) and their components. It involves applying a thin, non-conductive polymeric film that “conforms” to the board’s shape, creating a barrier against moisture, chemicals, dust, and extreme temperatures. Acrylic coatings are particularly cost-effective and easy to apply and repair, making them a go-to choice for many applications.

For example, a simple spray-on acrylic coating can prevent short circuits in a consumer electronics device exposed to high humidity, saving significant warranty and repair costs. Applying these coatings requires minimal equipment, and their thin application doesn’t add significant weight or volume to the final product.

2. Potting and Encapsulation with Epoxy Resins

Potting involves filling an entire enclosure containing an electronic assembly with a liquid compound, which then hardens to protect the components inside. This method offers superior protection against physical shock, vibration, and harsh environmental conditions. While it may seem more involved than coating, using a cost-effective epoxy for electronics can make this an accessible solution.

Epoxy resins provide excellent adhesion, mechanical strength, and chemical resistance. This technique is particularly useful for sensors and power supplies that operate in demanding industrial or outdoor environments. By completely encasing the electronics, potting creates a solid block that is nearly impervious to external threats, drastically reducing failure rates due to environmental exposure.

3. Using Enclosures and Housings

Sometimes the simplest solution is the most effective. Placing electronic components inside a well-designed enclosure provides a fundamental layer of physical protection.Cost-Effective Ways to Protect Your Electronic Components Inexpensive plastic or metal housings can shield circuits from dust, accidental contact, and minor impacts. For many consumer and industrial applications, a standard off-the-shelf enclosure is sufficient.

For instance, a simple ABS plastic box can protect a hobbyist’s Arduino project or a small control unit in a factory. To enhance protection, you can add gaskets or seals to improve resistance against moisture and dust ingress, often for a minimal additional cost. This approach is highly effective for prototyping and small-scale production where custom-molded solutions would be prohibitively expensive.

4. Proper Thermal Management

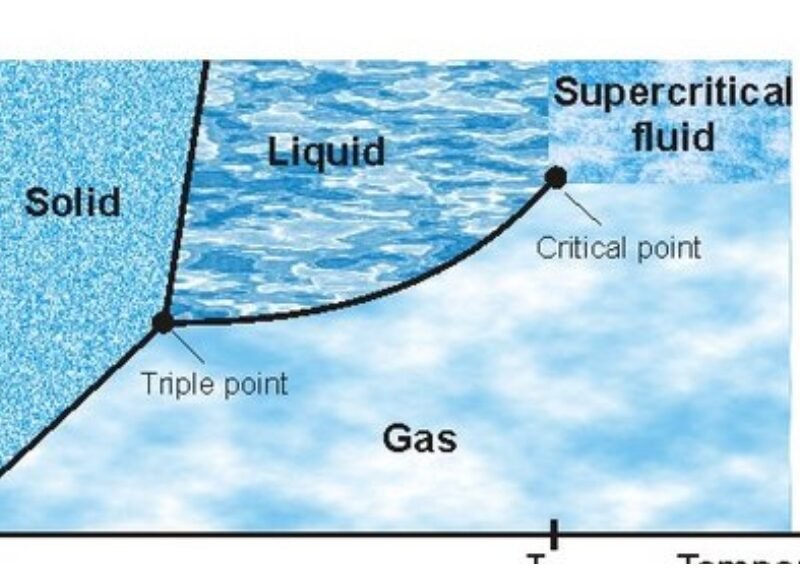

Overheating is a primary cause of electronic component failure. Implementing cost-effective thermal management solutions can significantly improve reliability. Simple heat sinks, which are widely available and inexpensive, can be attached to heat-generating components like processors and voltage regulators to dissipate thermal energy.

Another affordable technique is to ensure proper ventilation within the device’s housing. This can be as simple as strategically placing vents or adding a small, low-cost fan. For example, in a home server setup, adding a few dollars’ worth of heat sinks and ensuring clear airflow can prevent CPU throttling and extend the hardware’s life. These passive and active cooling methods are a small investment compared to the cost of replacing burnt-out components.

5. Applying RTV Silicone Sealants

Room Temperature Vulcanizing (RTV) silicones are versatile sealants that cure at room temperature to form a tough, flexible rubber. They are excellent for sealing gaps, protecting specific components, and providing vibration dampening. RTV silicones are affordable and easy to apply directly from a tube, making them ideal for targeted protection. You can use them to seal connectors from moisture, secure wires against vibration, or insulate high-voltage components.

For instance, a dab of RTV silicone on a wire-to-board connection can prevent it from loosening in a high-vibration environment, such as in automotive electronics. Their flexibility also allows them to absorb thermal expansion and contraction, reducing stress on solder joints.

6. Implementing Overcurrent and Overvoltage Protection

Protecting electronics from electrical hazards is just as important as shielding them from physical ones. Power surges, short circuits, and electrostatic discharge (ESD) can instantly destroy sensitive components. Fortunately, incorporating basic protection is inexpensive. Fuses and circuit breakers are classic, low-cost solutions for overcurrent protection. For overvoltage, components like Transient Voltage Suppression (TVS) diodes and varistors can be added to the circuit design for just a few cents per unit. For example, adding a simple TVS diode to a USB port’s data lines can protect the main processor from ESD events, a common failure point in consumer devices. These small additions are a vital and budget-friendly insurance policy against electrical damage.

By integrating these practical and economical solutions, you can significantly enhance the durability and reliability of your electronic components. Protecting your hardware doesn’t have to be a costly endeavor; strategic use of coatings, enclosures, and basic electrical safeguards can ensure your devices operate effectively for years to come.If you need more details to WORD US MAGAZINE visit.