The utilization of a pressure controller is better than mechanical valves,Why Use The Electronic Pressure Regulator especially in efficiency and design. The electronic proportional pressure regulator creates a specific temperature and pressure during a chemical reaction. The quality production process is possible when you have complete control over the chemical reaction. This is essential for maintaining the positioning of a company in the marketplace.

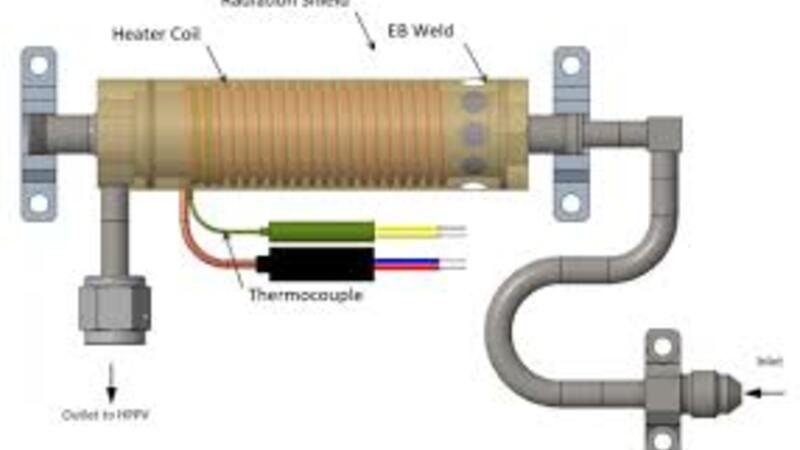

The proportional pressure regulator is commonly used in industrial processes to ensure the specific pressure during a chemical reaction. The tire curing electronic pressure regulators are efficient devices that ensure the specific level of pressure during a chemical reaction.In the following article, we discuss the various applications of electronic pressure control in the processes:

Control of Reaction:

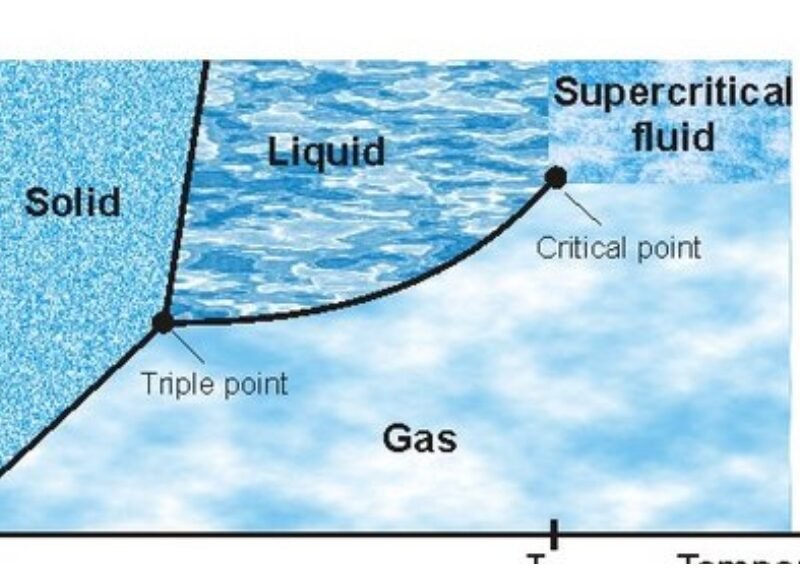

The proportionality of the chemicals is a critical thing in a chemical reaction.Why Use The Electronic Pressure Regulator You need to ensure a specific level of ratio of the reactants during a chemical reaction. For example, to produce a chemical, it is necessary to ensure the ratio of the reactants. This can be understood by a simple example, considering you are going to produce a chemical A by mixing the molar contraction of Chemical B, C, and D.

- Specific level of atmospheric pressure: In some chemical reactions, you need to produce a certain level of pressure to ensure a specific quality of the chemical. The electro pneumatic regulator is installed at various places to ensure a specific level of atmospheric pressure. The other thing essential in the chemical reaction is the proportionality of the reactants in the chemical reaction.

- Specific molar concentration: You need to mix these chemicals in a ratio of 20%,30%, and 50%. This is essential if you are going to produce a certain chemical. In this case, an electronic pneumatic regulator is great to ensure the specific molar concentration of the chemicals. The proportional ratio of the chemical is ensured by ensuring the specific contraction of the reactants. The role of the tire curing electronic pressure regulator is critical in producing a chemical of the desired proportionality.

Quick Response Time:

The electronic pressure control responds quickly in responding time, and you are readily able to give commands. The whole process is remotely controlled, and you can start and close the chemical reaction according to your desire.

- Production of Specific Formula: The role of pressure regulators is vital in the Pharma industry. The top-notch companies have complete control over the chemical process. The prime examples are GSK and Morris, and Phillips are well accepted by Pharmacists.

- High-quality medicines: The main reason behind these companies is the use of high-tech tire curing electronic pressure regulators to produce high-quality medicines. When the physicians are recommending the medicines of such top-notch companies, they know these medicines produce the best results.

Conclusion:

The utilization of the tire curing electronic pressure regulator is vital in the industrial process. With such efficient devices, you can control the quality of the production process. Control over the whole production process is essential for production according to SOPs. The quality production process is possible when you have complete control over the chemical reaction. This is essential for maintaining the positioning of a company in the marketplace.If you need more details to WORD US MAGAZINE visit.