Every business in the packaging production industry seeks the most efficient, precise, and high-quality packaging possible. Today, one of the most effective methods of printing in the packaging industry is flexographic printing. This remarkable printing system flexographic dominates the competition by seamlessly delivering long-lasting and vividly colored packaging that meets the grueling demands of all businesses and consumers.

Consistently, numerous companies consider flexographic printing to be the most efficient method of producing modern packaging. With the continued demand for high-quality production, the benefits of flexographic printing makes certain packaging have unrivaled aesthetic and member function.

Let us examine the reading material more intensely to increase interest in flexographic printing. We shall undertake an inseparable analysis of the advantages in packaging production systems and the significant functions of machines like plastic bag making machines.

Understanding the Flexographic Printing Process

Flexo printing is a modern take on the rotary letter press printer. This method utilizes relief plates that are flexible to adapt to the material surface. The ability to print on these various materials makes the process ideal for printing packaging. The substrates can include plastic, paper, foil, and even intimately used textiles.

Pace of work and being able to produce immeasurable volumes of products in a given time frame, Flexographic printing is tailor-made to suit the needs of the retail and packages and limited to the food industry and the pharmaceutical industries as it is versatile and offers fast prints of high quality even on flexible surfaces.

Important Steps in the Flexo Printing Process

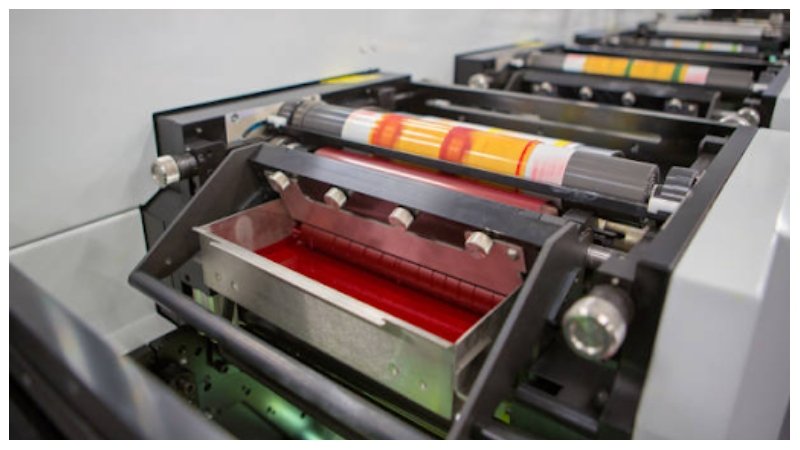

- Plate Preparation Steps: In flexo printing, a printing plate is prepared as the very first thing. The design on the plate is engraved onto the flexible polymer or the rubber, after which, it is fixed onto a cylinder.

- Ink Application: The plates are then treated with fast drying inks of low viscosity, which usually are water-based, UV-curable or, solvent-based, depending on the substrate.

- The Printing Process: The substrate which may include a plastic film, paper, or the likes, is in contact with the ink plate in a way that the image is pressed onto the substrate. The flexibility of the plate enables it to hold ink at a proper ratio thus allowing the image to hold proper shape even on surfaces that are uneven.

- Drying/Curing: The printed substrate then goes to the step of drying or curing depending on the type of ink used. In this step UV or air drying tech to make sure the ink sticks to substrate and the overall print is dry and visible.

- Finishing: The last step involves cutting and rolling the printed materials or doing additional processing until reaching the final product (for example, flexible packaging for multiple goods).

Advantages of Flexographic Printing for Packaging

Among other packaging production methods, flexographic printing has the most advantages. The most notable advantages include the following:

- Speed and Efficiency: Flexo printing is one of the fastest printing methods and is suited for large volume production. All long production runs remain up to the same quality, which is essential for industries that have a large packaging requirement.

- High-Quality Output: Fine details and bright colors are the signature of flexographic printing. Its attention-capturing packaging sells the product and brings more bang for the buck.

- Versatility: Flexo printing can be conducted on flexible films and rigid substrates, which gives it an unmatched flexibility in meeting the packaging needs of diverse companies.

- Cost-Effective: Other printing methods tend to be more expensive than flexo printing, especially when production runs are high. The same applies when a business is looking to trim production and material cost to maximize savings.

- Sustainability: Although flexographic printing has its drawbacks, its use of eco-responsible inks and energy efficient curing makes it a greener choice than other printing methods.

Flexographic Printing and Packaging

Like any other production process, the integration of flexographic printing into the workflow requires careful selection of the ancillary equipment to achieve the desired efficiency. Packaged equipment suppliers of polybag machines, plastic bag making machines, and the like certainly help to achieve the desired efficiency in the workflow.

With polybag machines, flexographic printers are able to automatically produce bags with intricate multi-colored designs and custom prints done in a single process. This coupled workflow increases efficiency by minimizing turnaround and lead time, thus shortening the entire production cycle. In addition to that, the use of advanced printing and high performance packaging machines further enhances the ability to offer competitively priced, quality, and attractive packaging.

The Use of Polybag Machines in Flexographic Printing

Polybag machines are one of the basic equipment for making flexible pouches and bags. The machines produce films and bags out of polyethylene, polypropylene, and other polymer films. The bags are used in a variety of applications for retail, food, and pharmacy.

When flexographic printing is used in the production of polybags, users can design and print the bags in bulk order. Primary level printing machines can print delicate motifs, tag lines, and intricate logos, and still keep the bags functioning as supposed to. This helps in creating wanted, durable packs. These can also serve as valuable promotional resources.

Major Pros of Melding Flexographic Printing with Plastic Bag Making Machines

Businesses that require efficient and durable packing solutions can take advantage of splicing flexographic printing with plastic bag making machine for sale. Some of these may include the following.

- Added Value Services Flexo printing services provide intricate and various styles of bag detailing. This helps with branding and making the bag visually appealing to customers.

- Increase TM Automation of printing and bag production Apple Ltd. & Com. can double the production volume and decrease TTM. The quality of the bags is not compromised.* Expenditure Minimization: Integrating flexographic printing with plastic bag making machines minimizes material waste and lowers production costs. The direct printing onto packaging film eliminates costly and time-intensive intermediate steps like label application.

The Future of Flexographic Printing in Packaging

With advancements in technology, the packaging industry has seen faster, improved quality, and more sustainable flexo printing. Companies with modern flexographic systems and high-performance polybag and plastic bag making machines will be able to prefer the increased demand for high-quality customized packaging.

Besides, the integration of digital technologies with flexography has improved business opportunities to create more elaborate and dynamic designs. In the next few years, flexographic printing automation, production speed, and eco-friendly solutions will continue to grow.

Conclusion

Packaging production has easily been benefitted from the improved efficiency, precision, and quality that the flexographic process has integrated. By incorporating it with machines like the plastic bag making machines for sale and poly bag machines, companies can simplify the production process and do targeted, high volume packaging.

With the constant evolution of the packaging industry, the requirement for affordable, easily accessible, and environmentally sustainable packaging will further enable the rise of the industry. With the proper deployment of flexographic printing and appropriate machinery, competitive companies will easily rise above the current competition. Click here for more information.