Modern businesses rely on well-chosen equipment to maintain smooth workflows, reduce delays, and support growing performance demands. Strong operational systems start with reliable tools that match the company’s goals, workforce skills, and production cycles. When leaders select equipment that boosts speed and accuracy, teams complete tasks with fewer disruptions. This approach creates a steady rhythm across departments and lowers long-term costs. Companies also strengthen safety and reduce downtime when they invest in tools that align with daily workloads. As technology evolves, smart equipment choices help businesses respond quickly to market changes while protecting overall productivity and service quality.

1. The Connection Between Equipment Quality and Daily Output

Reliable equipment drives consistent performance throughout the workday. Teams finish tasks on schedule when their tools function smoothly and support the pace of customer demand. High-quality machines reduce repair costs and prevent sudden disruptions that slow operations. Strong equipment also helps workers avoid unnecessary strain, which keeps morale high and lowers turnover. Businesses improve planning accuracy when they depend on tools that deliver the same results every time. Leaders who focus on quality experience fewer setbacks and enjoy a more predictable workflow. This steady environment supports strategic growth and builds trust across departments and with clients.

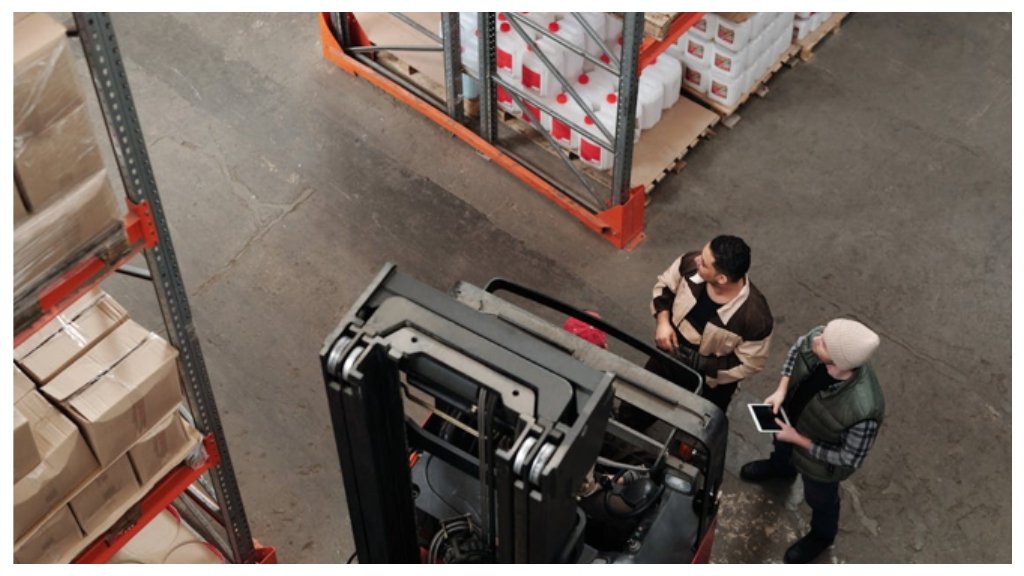

2. Why the Right Tools Reduce Downtime and Strengthen Workflow

Efficient tools keep operations steady by allowing teams to move through tasks without unnecessary delays. Warehouses, distribution centers, and manufacturing facilities depend on conveyor belts and forklifts to handle heavy loads, speed up material movement, and maintain consistent workflow patterns. When these machines operate with precision, workers avoid jams in aisles, prevent loading errors, and stay on schedule. Strong equipment performance also helps managers plan shifts, coordinate deliveries, and reduce bottlenecks during peak hours. Businesses that rely on dependable components, including Moffett parts for Moffett forklifts, experience fewer interruptions and maintain tighter control of their daily operations. This stability protects valuable time and supports long-term productivity gains across all material-handling tasks.

3. How Smart Investments Improve Cost Control

Equipment that matches a company’s operational needs helps leaders manage expenses more effectively. Well-selected tools require fewer repairs, use energy efficiently, and support longer life cycles. These advantages allow businesses to allocate budgets toward expansion instead of constant maintenance. When teams work with machines that deliver consistent output, managers forecast costs with greater accuracy. Strong investments also reduce the need for emergency replacements, which often strain financial plans. Forward-thinking companies monitor performance data to decide which tools offer the greatest return. This careful approach strengthens financial resilience while helping businesses maintain a competitive edge in demanding markets.

4. The Role of Equipment in Advancing Employee Performance

Employees deliver their best work when their tools support comfort, safety, and precision. Modern equipment designs help workers stay focused by reducing physical strain and simplifying complex tasks. Teams gain confidence when they operate machinery that responds accurately and handles demanding workloads. Businesses that prioritize ergonomics notice fewer injuries and a more motivated workforce. Improved equipment also speeds up training, allowing new employees to learn processes quickly and contribute sooner. These advantages raise overall performance levels and help companies meet tighter deadlines. When employees trust their tools, they maintain strong efficiency and produce reliable, high-quality results.

5. How Technology-Driven Equipment Enhances Accuracy and Speed

Advanced equipment powered by modern technology increases accuracy while shortening task times. Automated features help workers reduce errors and maintain consistent output across repeated processes. Digital controls offer precise adjustments that support complex production requirements. Real-time data tracking also helps managers monitor performance and make informed decisions quickly. Businesses benefit from faster turnaround times when equipment responds smoothly to changing demands. Technology-driven tools allow teams to complete more work without sacrificing quality. This combination of speed and precision strengthens operational efficiency and positions companies to handle growth, seasonal fluctuations, and competitive pressures with greater confidence and stability.

6. How Maintenance Strategies Keep Operations Running Smoothly

Strong maintenance practices keep equipment reliable and ready for daily demands. Teams follow clear schedules that prevent small issues from growing into major setbacks. Skilled technicians inspect machines regularly and act quickly when they spot early signs of wear. Managers track performance trends and adjust routines to match usage patterns. This disciplined approach protects productivity and supports consistent output. Businesses that commit to proactive care save money, protect worker safety, and reduce the risk of sudden breakdowns. Well-maintained tools help companies meet deadlines with confidence and sustain efficient operations across every department.

7. The Influence of Equipment Compatibility on Workflow Coordination

Equipment that works well together strengthens coordination across tasks and departments. Smooth compatibility helps teams transfer materials, information, and responsibilities without delays. When tools align with each other, workers experience fewer interruptions and maintain a steady rhythm throughout the day. Managers choose machines and systems that support shared goals and streamline communication. Strong compatibility also reduces training time because employees move confidently between connected tools. These advantages encourage collaboration and lower the chances of miscommunication. Companies that focus on compatibility create a unified environment where technology, people, and processes all support consistent performance and reliable outcomes.

8. Why Customization Options Support Better Resource Management

Businesses improve resource management when they select equipment that offers flexible customization options. Adjustable features help teams tailor machines to specific workloads, unique operational goals, and industry requirements. This flexibility allows managers to fine-tune performance and reduce waste. Companies also gain the ability to scale production without major replacements because customizable equipment adapts to new challenges. Workers benefit from tools that match their techniques and reduce unnecessary effort. When businesses control how equipment performs, they optimize energy use, prevent overuse, and extend machine life. This strategic approach supports long-term sustainability and strong operational balance.

Operational efficiency grows stronger when businesses choose equipment that supports accuracy, speed, safety, and reliability. Each decision shapes daily performance, long-term stability, and overall competitiveness. High-quality tools allow teams to work confidently, maintain steady output, and deliver results that satisfy customers. Strong maintenance, compatibility, customization, and planning all contribute to smoother workflows and better financial performance. Companies that treat equipment as a strategic asset position themselves for continuous improvement and long-lasting growth. Click here for more information.