The landscape of food preservation has undergone a significant transformation with the advent of innovative technologies like Industrial IQF freezer tunnels. Understanding Industrial IQF Freezer Tunnels These sophisticated systems enable the rapid freezing of individual pieces of food. Locking in freshness and extending shelf life. By utilizing extremely low temperatures and swift processing times. IQF technology ensures that the quality, texture, and nutritional value of food products are impeccably maintained. The benefits of such advancements are profoundly felt across the food industry. from farmers to consumers. Keep reading to delve deeper into the intricacies of these revolutionary freezing methods and the impact they have on our daily lives.

Exploring the Basics of Industrial IQF Freezer Tunnels

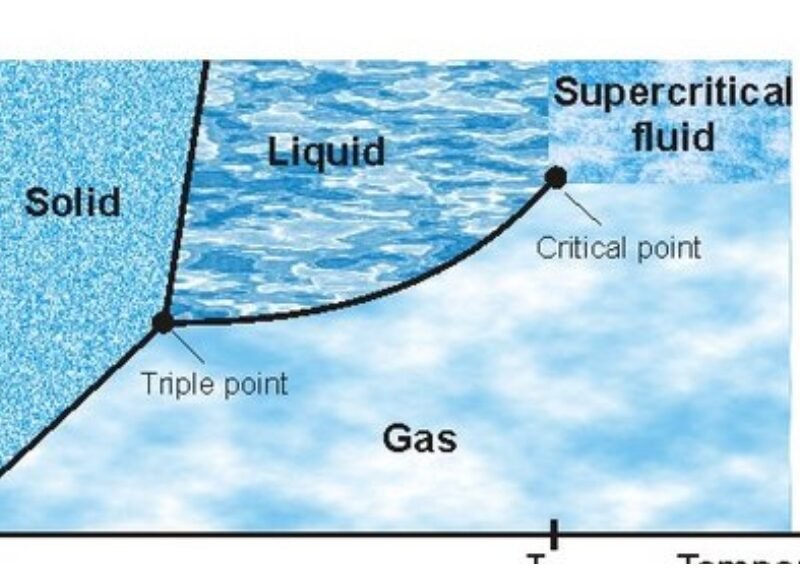

Industrial IQF, or Individual Quick Freezing, freezer tunnels represent a cutting-edge approach to food preservation. At the heart of this process is the ability to freeze each food piece separately. which prevents the formation of large ice crystals that typically damage the cell structure of the product. This remarkable method not only preserves the original quality but also simplifies portioning and packaging for food producers.

These tunnels are carefully designed to accommodate a variety of food products. Including fruits, vegetables, seafood, and meat. As products enter the tunnel on a conveyor belt. They are subjected to blasts of cold air, often at temperatures dipping below -40 degrees Fahrenheit. This swift and consistent application of extreme cold is crucial for achieving the quick-freezing effect desired in IQF processes.

The Role of IQF Technology in Food Preservation

The fundamental role of IQF technology in food preservation is rooted. in its ability to maintain the cellular integrity of frozen products. Unlike traditional freezing methods, which often result in the formation of large, damaging ice crystals. IQF technology promotes the rapid crystallization of water within each individual item. This quick-freezing action is less destructive to the natural texture and structure of the food.

By preserving the original characteristics of the food. Understanding Industrial IQF Freezer Tunnels IQF technology plays a pivotal role in ensuring that the nutritional content. flavor, and appearance remain virtually unaffected by the freezing process. This level of preservation is essential for consumers seeking high-quality frozen products that closely resemble their fresh counterparts in every aspect.

Additionally, the IQF method aids in reducing food waste. The ability of these systems to freeze products individually means that consumers can conveniently defrost and use only the necessary amount of food. leaving the rest safely frozen. This aspect is instrumental in curbing the excess discarding of perishable items.

Advantages of IQF Freezing Over Traditional Methods

IQF freezing presents several advantages over traditional freezing techniques that collectively contribute to its growing popularity. One of the most significant benefits is the minimal clumping of products. Allowing for better portion control and easier processing post-freezing. This characteristic is especially beneficial for frozen food producers that require precise product quantities for packaging and distribution.

Another key advantage is the improved product quality achievable with IQF freezing. By reducing the formation of large ice crystals. IQF preserves the color, shape. And texture of food items, making them more appealing to consumers. This translates directly into higher satisfaction and potentially greater sales for food companies harnessing this technology.

Energy efficiency is another area where IQF systems excel. Designed with modern insulation and refrigeration techniques. These systems consume less power while providing superior freezing capabilities. The reduced energy expenditure not only lowers operational costs but also aligns with environmentally sustainable practices within the food industry.

Emerging Trends and Future Developments in IQF Freezing Technology

The evolution of IQF freezing technology is shaped by ongoing research and development. Aimed at improving efficiency, quality, and environmental sustainability. One of the emerging trends is the integration of more advanced automation solutions within IQF systems. Automation not only enhances precision but also minimizes the need for human intervention, which can increase productivity and reduce labor costs.

Sustainability is at the forefront of future developments in IQF technology. Engineers are working on next-generation refrigerants with lower global warming potential. as well as energy recovery systems that reduce the overall carbon footprint of the freezing process. These initiatives are pivotal to meeting the increasing environmental regulations and consumer demand for more sustainable food processing methods.

Overall, the potential of Industrial IQF freezer tunnels in transforming the food preservation industry is immense. These systems offer a host of advantages over traditional freezing methods and are continually being optimized for energy efficiency, environmental sustainability, and superior food quality. As we look to the future. it’s clear that IQF technology will remain a cornerstone in the advancement of food processing and distribution, benefiting producers and consumers alike.If you need more details to WORD US MAGAZINE visit.